Precast Pre-stressed Concrete Products

Using BGA pile solutions means your project...

read morecheck out some handpicked work we’ve done for our lovely customers

Transportation of piles as well as the tensions created during pile driving is the main cause of tensile stress. Due to the innate weakness of concrete against tensile stress, cracks typically occur in ordinary reinforced concrete pile sections. In traditional piles, tensile strength is provided by steel rebar. Unfortunately, the reinforcing bars deform longitudinally during transport and installation and consequently sectional cracks are created in concrete.

In corrosive environments, these cracks lead to damage to steel and concrete by penetration of chlorine ion, Sulphates, alkaline reactions, etc. To complicate matters more, inspection and evaluation of integrity of traditional concrete piles after installation are challenging as these elements are not accessible by visual inspection.

Some consultants mainly focus on the superstructure and calculate pile structural strength and resistance, whereas serviceability load during transportation, erection and installation must also be calculated.

In section 3, Australian Standard Piling – Design and installation AS2159 emphasizes the requirements and procedures of considering serviceability loads in pile design. If superstructure loads, transportation and installation influences, seismic loads, ground movements, adhesion of soils and parameters of durability and design life mentioned in section 6 of Australian Standard AS2159 are considered, the parameters of pile design, in corrosive environments, traditional non-prestressed piles must be excluded as an option.

Centrifugally manufactured concrete creates a higher density, hardened concrete compared to cast-in-place method making sure that no cracks are created along the shaft of the pile when pre-stressing is added. This means no damage to the piles during transportation and installation.

To summarize, prestressed manufactured piles results in very high strength concrete guaranteeing the durability and design life of piles after installation.

You can see BGA's services here.

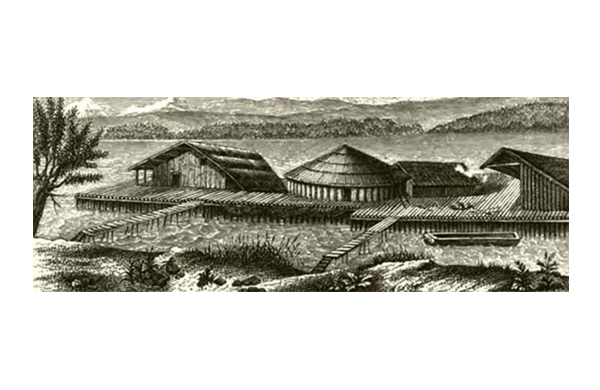

Herodotus(400 b.c.): Paeonians had houses build over timber piles driven into the river bank

Prehistoric: - Babylon, Cedar Timber Piles - Paneonia, Timber Piles in river bank

- Middle-age: Venice and Holland, Wide assortment of structures

19th Century: appearance of concrete, Concrete piles - Australia 1925 - Japan 1970 - Koria 1994 - 90% Pile production is PHC piles - Singapure - India - Malaysia

Iran 1340’s: Bandar Iman Petrochemical Complex

Bidboland, Makin Darya Kish, Zharf kar Jam and ...

you can see latest news here, for more please visit news menu.

A Solid Foundation For Your Investment